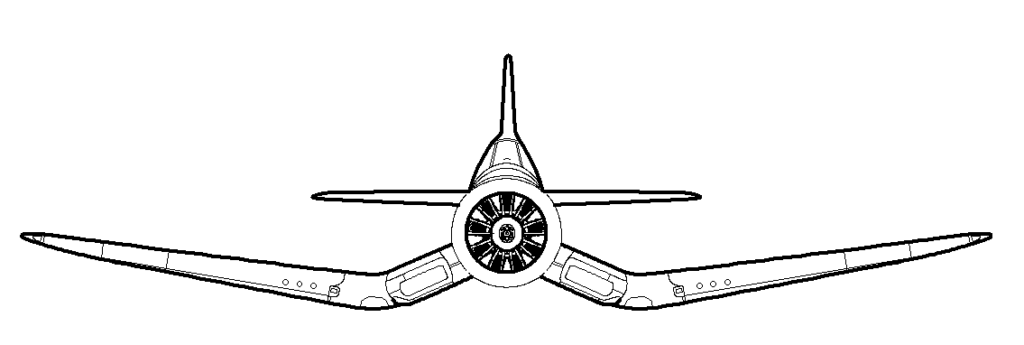

F4U Corsair Projects

Where we are today…

CEO, NuLANtek, Inc.

Before I ever built anything for a Corsair, I knew that the process I started out with would not be the same when I finished. …and I was right.

The day I went to the factory to purchase my first CNC router, I asked the sales guy if I could just make the entire aircraft without having to do all of the layups and foam and shaping. He said that I could and took me into another room so I could see a custom machine that was cutting cartoon characters out of foam for an amusement park. He described that process and I knew that is where I had to go.

It’s now many years later and many of the aircraft companies have moved away from the process Burt Rutan made so popular back in the 70’s to the same process I saw that day. It’s now all about 3D printers and 5 axis routers.

Version 2 used the Rutan method and I got far into the development process before I found myself, yet again, looking for a new shop.

Version 3 takes the exact same design as V2, but converts everything to a Solid Model. From there I will have our friends at REVELAERO cut the model in foam using their big machine. Once the model has been finalized and adjustments made, we will invert the design and make the molds.

So, let’s get started with a new approach…

I could go faster if I had my own equipment but Investment dollars are hard to find in the age of Covid.

However, I will say: donations are welcome!